06 September 2021

|

When it works, we ignore its existence, when it doesn’t, we can be tempted to lose all patience. Wiring is perhaps the railway modellers’ least favourite subject to become enthused about, but it’s a necessary requirement to permit all of our track-powered models to function.

The way you wire your layout is specific to the way your tracks are positioned, hence a ‘one wiring diagram fits all’ becomes impossible, but there are some common tips that you’ll find useful when wiring a model railway.

1. Keep all of your wiring tidy

Wires shouldn’t be left to dangle loosely underneath, particularly if your layout is to be made transportable. Zip-ties are a great way of ensuring that cables are kept in neat bundles and are easily traceable.

2. Use colour-coded wires

Even with a DCC layout, despite it in theory, having no ‘positive’ or ‘negative’ rail, you should use a different colour for each. Change colours for your bus cables and bundle these neatly together, away from your running lines. Some advocate the twisting of certain wires to cancel electromagnetic interference on large layouts, though the majority of users shouldn’t encounter problems if this isn’t observed. For large DC-controlled layouts, many different cable colours are likely to be required, hence you’ll need to invest in colour-coded wires with a tracer colour. Their use prevents the necessity of using the same colour for more than one application, making the pinpointing of potential problems in the future much faster.

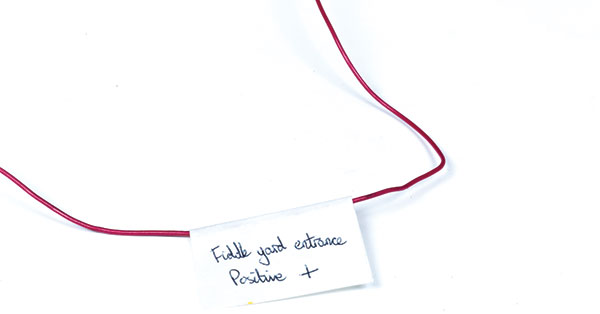

3. Label your wires

Three wires underneath your baseboard that disappear to the underside of the rails in the direction of a point can be difficult to identify when the topside has been ballasted. If your layout is complex and you have crossovers, or a double slip, the problem can be compounded further still. Coming back to these after a few years to trouble-shoot a problem or correct a fault can mean nothing if you’re not sure what each one does. A small label on each wire costs nothing and can save a great deal of time later with a multimeter.

4. Use a wire-stripper

Don’t strip cables with a knife as you might cut through strands of the wire, too. This tool makes quick work of cutting cables neatly and stripping wires the correct amount. Its lower part has a guillotine-action cutter, while its top part has an adjustable pre-set cable strip limit. Wiring your layout is so much faster, too.

5. Twist and tin wires

When using terminal blocks underneath a baseboard for power distribution, I prefer to twist and tin the wires to protect them before tightening the screws in the blocks. Some say that this can create electrically dead or ‘dry joints’ with time – we’d say they’re not screwing the wires in tightly enough and cleaning the solder after use. The softer solder allows the screws to ‘bite’ into the cable better. I’ve never encountered a problem with wires coming loose or dry joints on layouts that have travelled across and from continental Europe to the UK.

6. Know the resistance

‘Resistance is futile’ say all the movie villains, but when wiring a layout, understanding this principle is paramount. Resistance is the ability for a given amount of current to pass through a cable. Think of your model railway controller as a bath full of water that is being filled rapidly. Let’s assume that the cable is too thin – the plug hole. The plug hole will only allow a given amount of water to pass through – the current. Too much current through the cable will overheat the cable and in the worst of scenarios might melt the insulation leading to a fire. The correct wire for your layout should be based on the maximum current being emitted by your controller with a safety margin of around 15%. Tables for these can be found online.

Struggling to decide on the right DCC decoder for you? Our guide here should be your first port of call.

If you'd like advice on how to set up a DCC decoder, our easy-to-follow tutorial should be your first stop.

For more advice on about DCC, head to our dedicated section.