21 December 2020

|

I need a coaling stage for my OO gauge layout but can't find one that fits the space and my budget. Can you suggest anything? Dave, Douglas.

You don't say what sort of layout you are building, but assuming a typical branch line, I have something that should do the job. Coal stages for smaller engine sheds tended to be made locally, and often in wood. We can do the same, in fact, if, like most modellers, you have a supply of wooden coffee stirrers, then this will be a very cheap project.

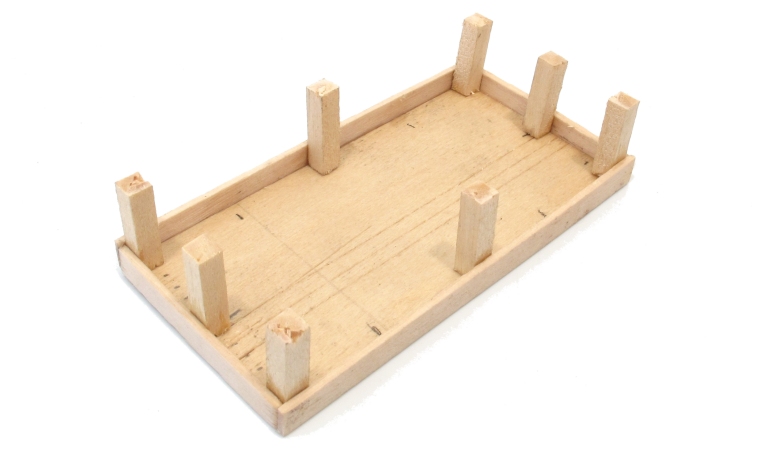

The “kit” for this project. A pile couple of lengths of 1/4” (roughly 4mm) square basswood, some 1/8” (2mm) thick plywood and several wooden coffee stirrers.

The floor is cut from plywood using several passes of a heavy knife. My model is 80mm by 40mm but the size can be modified to fit the space available. Use the knife to score plank lines along the floor.

Stirrers are cut to length to edge the floor.

The floor should be low enough that the side door of a wagon can be opened onto it. In this case, 19mm seemed about right. Too low is better than too high.

Legs are cut to raise the floor to the right height. Take time to ensure all are the same length and reasonably square.

Split a couple of stirrers along its length to narrow them. These are cut and fitted as diagonal braces on the legs. The pattern varies between prototypes but an inverted V makes sense to me. Engineers can write in and tell me I'm wrong...

The sides are three layers of stirrers. It's worth checking that they are all the same width, I had to trim a couple down to make them match. The uprights are more split stirrer from the last step. Sorry about the leg waving in the air – the model does sit flat, the studio surface obviously wasn't!

A quick coat with EDM Models "Weathered Wood" turns the wood a silver-grey colour. This dries fast and, if you prefer a darker shade of grey, extra coats can be brushed on.

Break some coal up to make a pile. I prefer to crush lumps with pliers rather than hitting them with a hammer. It's a lot less messy this way, plus you have more control over the lump size. Fix the pile using a 50/50 mix of PVA and water applied sparingly. We want to soak the coal but not the wood.

Weathering starts with a wash of thinned black enamel. Allows this to dry for a few minutes and then attack the whole structure liberally with black weathering powders.

After this, the coal stage just needs to be bedded into the layout, and then a bit more dropped coal scatter around the legs.

Do you have a model railway question - send it in and we'll answer it.