09 June 2022

|

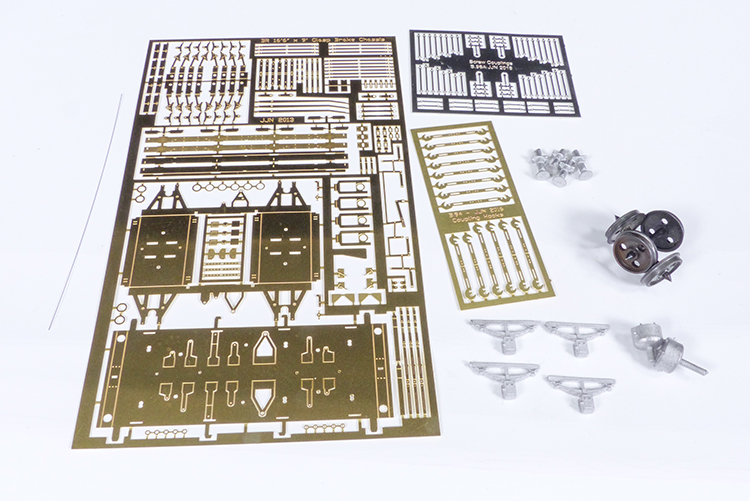

Howard Smith constructs a highly-detailed etched brass chassis underframe kit from Rumney models – an ideal way to upgrade older mineral wagons.

With each model release of new highly-detailed rolling stock, a lack of detail on older models becomes more obvious. If a model’s weak point can be made into one of its star qualities, older rolling stock can be given a fresh lease of life and still attract views of admiration.

Rumney Models produces etched kit upgrades to compliment, replace, or upgrade detail on many RTR items. Many of these kits could be described as advanced, aimed at modellers with experience and confidence in etched brass kit construction. I was keen to test its (B.01-B.05) Clasp Brake Chassis Kit, having seen images of assembled models on its website which defied their scale, looking every bit as accurate – perhaps even more so – than the latest RTR rolling stock.

Building tips for B.01-B.05 clasp brake chassis

- Soldering experience is advised before taking on this involved challenge

- If you’re hesitant about complexity of this build, download the instructions beforehand from the manufacturer’s website

- Build time estimated around 20 hours, being familiar with components, assembling a second wouldn’t take as long

- Patience is required and assembly can’t be rushed

What we noticed...

1.

The quality of parts supplied on the fret is excellent, all etched holes being to the correct dimensions, and fitment of parts requiring little to no adjustment.

2.

Parts are half-etched to the sprue, and the majority can be cut free with a scalpel. For smaller parts, more complex cutting with tin snips is required to avoid distortion of the brass.

3.

There isn’t much rivet detail to punch out on the chassis – the complex areas being already half-etched. A small punch is used, with a modelling mat underneath to push out those that aren’t, however.

4.

Guaranteeing a crisp 90-degree fold along half-etched lines isn’t always simple, and often you need to improvise. Here, two steel rules are used to fold the bottom of the headstocks.

What we like about this kit:

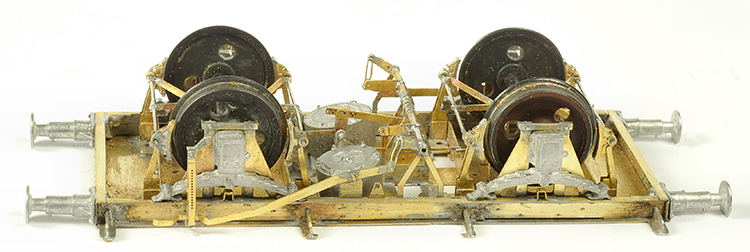

- Tab and slot construction helps alignment of intricate parts, while half-etched lines assist the folding of intricate parts into more complex components such as the brake gear

- The etches are very well designed – a credit to their designer. With this kit, OO, EM or P4 gauges are possible. I opted for P4 as I’ve never built anything in this gauge before, and widened the spacing of brake hangers too, according to the instructions

- Wheelsets are sprung. This alone requires a few hours to ensure that the sprung wire provided is trimmed, soldered and that the wagon sits correctly on its wheels. A test run before proceeding is recommended

A sigh of relief as the underframe is completed! An impressive model, though a time-consuming build.

5 tips for soldering success

- Cleanliness is key – each part cut from the fret should be cleaned, regardless of how little surface oxidisation it has

- The majority of components are cleaned with a fibreglass pen

- Keep your eyes and face at distance because fibreglass fibres have a tendency to fly

- Stray fibres stuck in your fingers are best removed carefully with tweezers

- Wire wool can also be used for cleaning, but is less precise for detail parts, can often snag on finer details and leaves behind a trail of steel wool strands which are readily attracted to motor magnets!

Enjoyed these tips? Find more model construction techniques, here.