03 December 2019

|

Here we give you our top tips to achieve impressive weathering results on any model, whether static or in motion on your layout.

We go to enormous lengths to build accurate miniatures of nature, structures, and railways – all portrayed in our chosen moment in time. Every little piece contributes to the overall picture or scene that we are endeavouring to create. Weathering is one of the primary tools to that end. Here are some top tips to help make your stock look more realistic.

Flattening Paint

If painting a kit, it's cleaned and given a coat of primer. For smaller scales, getting an airbrush out is worthwhile. All aerosols are extremely crude, leaving a poor finish, so once dry, rub surfaces with 1200 grit wet-and-dry paper to get rid of high spots.

Once the top coat is applied, use 2000 grit wet-and-dry paper to rub it down so it’s truly flat. fold the wet-and-dry into a 10mm x 10mm square, and use it wet, working the entire panel right up to rivet lines. It is regularly wiped clean to see how quickly bumps disappear.

With everything now looking matt, you have a choice - a light buffing will give it a gentle aged gleam for further weathering, or you could give it a full polish to give it an ex-works finish, where it would still benefit from extra distress.

Polishing models

Buffing with a paper kitchen towel gives enough shine, but we sometimes give models a wipe with Duraglit silver polish. Be quick though, so that solvents don’t disturb the paint. Buffing with the kitchen towel after a wipe with a polish gives a brighter shine, so use it with caution. T-Cut can be coarse and remove a great deal of paint that way.

If you try this process and your water turns a milky white colour, it’s because the model has been varnished. Don’t worry, the technique works well on varnish and creates the same effect. Go easy, though – you don’t want to break through the varnish layer, because it creates a tidemark that will be difficult to remove.

Transfers should be added at this point and left to dry, then fixed with varnish after application. If paint is properly flatted and buffed, the transfer carrier becomes invisible. They don’t appear to need anything further to fix them, so I no longer have to varnish them down.

Time for dirt

Locomotive dirt is generated by the locomotive, the environment, and track, and is partially removed by wind, rain, washing and cleaning. All these factors come into play when we choose how to weather our locomotives. We tend to build up a few layers, rather than just one weathering coat – even if the layers are very subtle. It adds to the depth.

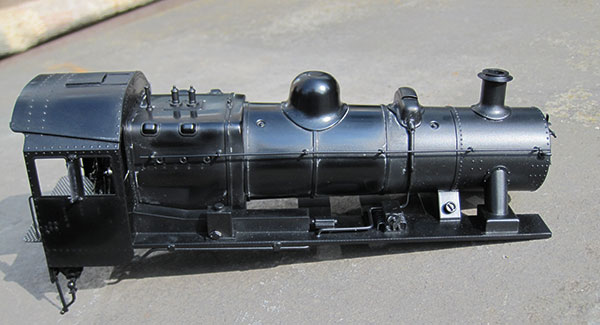

The Garratt was reasonably well-cared-for, but is fairly elderly and work-worn. The first treatment was working the boiler, cab, and tanks with Winsor and Newton ‘Lamp Black’. It’s a water-soluble oil paint, which can be moved around with a damp brush or wiped off. When applied to a colour like maroon, it stains the paint, giving it a really nice aged quality.

Brush small quantities into cracks, joints, rivet lines, bottoms of panels, then wipe most away with kitchen towel – always in a vertical direction. It leaves dirty weathered streaks. Don’t over-do it - you can always do more and it takes a day to dry. Enamel washes are a good substitute.

The chassis frames were stippled with a mixture of Humbrol Gunmetal Metalcote (ref.27004), Matt Black (ref.33), Tarmac (ref.112), with rust browns around the brakes. Talcum powder is added to texture the surface. For oily areas, a mixture of the black and gunmetal was worked into the wheels between the spokes.

The finish is achieved by applying a few small dabs of Humbrol Metalcote Gunmetal, then swamping it in enamel thinners – thus floating the paint around the whole plate, and while still wet, spreading talcum powder all over. Allow it to dry off, brush all the excess talcum off, and polish the plate with a kitchen towel. This gives the effect of clean, but worn black paint, with steel occasionally showing through. Any rust can then be added either with paints or powders as required.

The ash-pan was comprehensively rusted using Humbrol Gunmetal paint and talcum as a foundation, followed by stippling with rust colours. The nickel-silver valve gear was toned down using Humbrol Polished Steel (ref.27003) with a dash of Gloss Tan (ref.9). Details like worn cab rails and wear added to steps were done using Polished Steel (ref.27003).

Copper pipework was achieved with a mix of Metallic copper (ref.12) and Gunmetal (ref.27004), as unless copper-work has been polished recently it very quickly darkens – especially with hot water passing through it. Fittings, such as safety valves etc. were a mix of Metallic Brass (ref.54) and Gunmetal to darken it down.

Top Tips

- Flatten and polish paintwork

- Subtly pick out rivets and panel joints

- Paint and wipe away vertically to create layers

- Use talcum powder as a texture for rust and to matt drying paint

For more step-by-step weathering articles, head to our ‘Techniques’.

Read our step-by-step guide to weathering a locomotive using paint washes and powders here.