09 October 2019

|

The sky was the limit, or so it seemed, for this team of keen railway modellers who took part in Episode 5 of Series Two of the GMRC. Howard Smith went behind the scenes to discover more about the techniques they used.

Team Grantham took victory in episode five of Channel 5's Great Model Railway Challenge show. You'll be able to read our exclusive interview with the team in the November 2019 issue of BRM, on-sale now in stores, or available to download as a digital edition from www.pocketmags.com/brm.

Take a tour of their Alpine model railway in this video:

So, how was their victory secured? I quizzed Graham, Andrew and Tom from the team to find out more.

"The animations and wiring was interesting as it had to come to bits", says Graham. "Most of it was pre-wired before the show". As it happens, Andrew is very good at wiring. "He does it all in a logical and controlled manner"

Given that so much of the end spectacle relied on animations, how did the team find the creation of these?

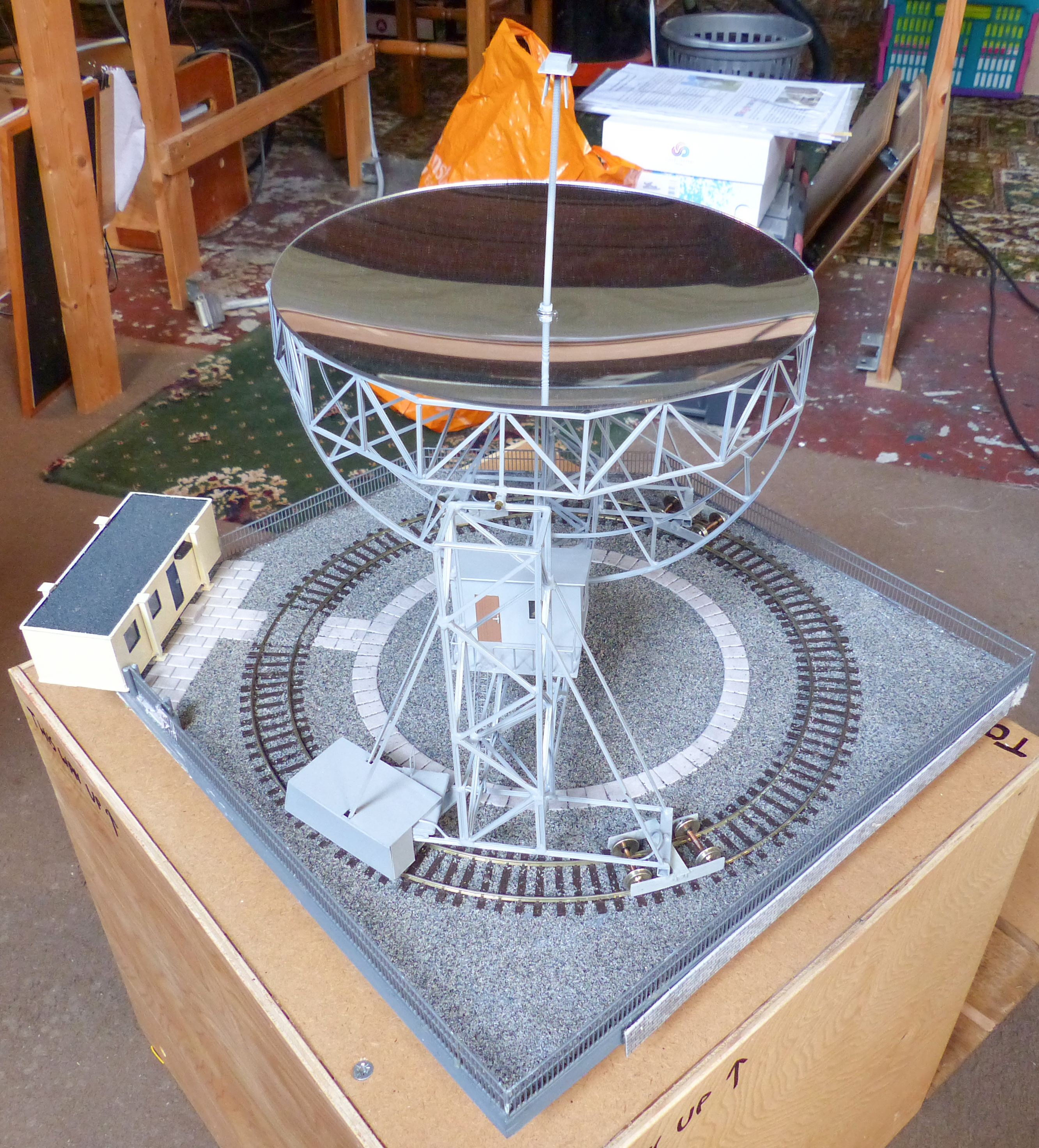

"It was Graham and I that were largely responsible for the effects", explains Andrew, "We had to use motors and old gearboxes from a box of bits we had lying around." "Yes, I mean the radio telescope has a motor from an old tram model and uses one of Andrew's fathers' old motors, too, just so that it can rotate." The funicular employs components from the same box of bits, as it happens. The six pre-built items helped the team make considerable progress with their build, the highlight of which was the telescope, built over a 24hr period.

One of six pre-built items by Team Grantham, a radio telescope, using soldered N gauge rail.

The team employed their time during the scratch-build challenge wisely, sticking with the theme to make a 'rocket fuel wagon' using zip-ties.

Was the performance on the day of the reveal as planned, however?

"Well, the mechanism for the rocket worked as it should, but all those second-hand parts required tweaking" said Andrew. "It's the little things that make the difference on the day, you know, like marking which way the controller should be turned to make sure the rocket takes off first time". Graham explains how the mechanism for the rocket works - a piece of wire, threaded through two wire loops, one end attached to the top of the rocket, the other to a small cable drum, in-turn rotated by an old locomotive motor and gearbox. A theatrical background helped no doubt in their reveal. "We bought a small smoke machine from Amazon for £30 and directed the smoke using cardboard ducting for when it took off"

What did Tom make of these animations and his time on the show?

"It all went very well", he says with an enthusiastic smile, "but wait until you see what we make next", he adds. "I really enjoyed adding the scenic details and we really worked well as a team. It was mostly because Graham's plan went as expected.

So why was the plan of action for the build so precise and why was Graham team leader?

"I started with British Rail in 1986 and met Andrew at the time. I was an Engineering Manager Trainee, specialising in railway stock, though I'm now semi-retired. I oversaw the approvals on the Class 66s for EWS in the UK and other countries", explains Graham. "With planning on a regular basis as we take layouts out to shows, it's something I find comes naturally", he explains. "Yes", interjects Andrew, "The planning sheet we had was really useful and we'd catch up in the pub every evening after the day had gone by just to see where we were with things." Handing me the planning sheet, Graham explains the Gant chart, which takes into account drying time for glues or paint and ensures that no member from the team of five was left unoccupied during the build. Tom adds, "The plan was great, but we had other things that helped us too, like the use of Setrack curves which avoided the need to cut rails when under pressure"

Another challenge from the scratch-build challenge - a flip flop, cunningly transformed into a path.

Read our exclusive interview with the team in the November 2019 issue of BRM, on-sale now in stores, or available to download as a digital edition from www.pocketmags.com/brm.