13 May 2019

|

The traditional method of scratch-building models is still the preferred choice for many modellers, however, 3D printing is growing in popularity, especially now there are more affordable printers available to buy.

Using computers with software to create virtual objects isn’t new. Automotive manufacturers have been using 3D printing to create tooling for mass-produced components for over 40 years now, but when it comes to model railways, it’s still very much in its infancy.

The growth and impact of 3D printing spans across many industries, including aviation, manufacturing, and health. BRM has explored 3D printing in the magazine on regular occasions and here we take a closer look at its capabilities, plus explore what the future looks like for 3D printing in the model railway world.

is 3D printing being used already in railway modelling?

Model manufacturers like Hornby and Bachmann have been doing 3D printing for years, ‘rapid prototyping’ as it's more commonly called, allows designers to see the results of their efforts and get a proper feel for the model they are making in a way that a picture on a screen doesn't allow.

The traditional method of scratch-building models is still the preferred choice for many modellers, however, 3D printing is growing in popularity, especially now there are more affordable printers available to buy.

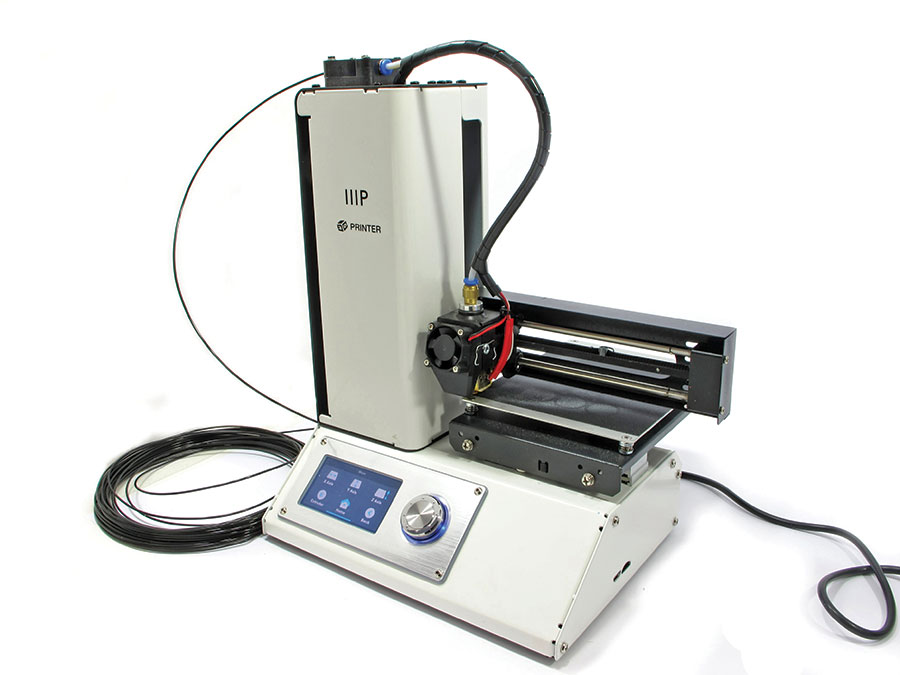

At the cheap end of the market, one would set you back less than a single OO gauge express locomotive. There are a few quality issues when you buy a cheaper machine, though, but if you fancy dipping your toe in the water, then they would be worth a look. Better quality means more expense, both in terms of machine and materials, but even here, prices are dropping.

How to use a 3D printer for model railways

Using a 3D printer requires gcode files, online there are hundreds of designs available that are free to download. CAD (computer-aided design) is used by model railway kit designers to create custom 3D parts, these designs are then put into a gcode format (the language for computerised machine tools), which is needed for the printer to be able to interpret the design.

There’s plenty of software to create virtual 3D objects. Some can be learnt in a day, others might take weeks. Prices vary wildly too from being free to a monthly subscription or a one-off payment.

Part of the learning process involves understanding the materials. Printing using Polylactic acid (PLA) can be really easy, non-smelly and provides a model that can be sanded if required. One problem is working out how much filament will be needed. If the design includes lots of supporting materials or infill, you can find the stuff disappearing at quite a rate.

One of the critical dimensions to consider when looking at 3D printers is the bed size, which is the print area the device can work on.

To see the use of CAD by a railway modeller, click here to read about Les Green’s Liverpool Lime Street.

How long does a 3D printer take to make model trains?

Depending on the machine, a small locomotive can take 2.5 hours to print and a larger (10cm long) toy, over 6 hours. Fortunately, once the first few layers have been laid down, the machine can be left to get on with the job. Whichever material you decide to have a model printed in, it will always benefit from some smoothing to remove remaining evidence of printing.

Flooding the model with multiple coats of paint or primer may fill the layers quite quickly, but will soften details. We mainly rely on abrasives to remove the stepping evident on a 3D print.

Top tips

- Use the best quality 3D printing materials you can afford. We’d recommend Frosted Ultra/Extreme detail from Shapeways.

- Spend time looking over the model, studying detail to be preserved.

- Ensure that a 3D print is cleaned thoroughly before applying paint.

- Don't flood the 3D print with paint.

Model materials for 3D printing

There are three main materials used for 3D printing:

- PLA – Poly Llactic Acid is a biodegradable polyester derived from corn starch or sugar cane. When heated for printing, the fumes (if you can smell them) are sweet. The resulting models can be sanded smooth with normal abrasives. As the material is bio-degradable, it can be disposed of in a compost bin, apparently taking 6 months to dissolve. Nozzle temperatures of around 200ºC are required but while a heated print bed is desirable, it isn't essential.

- ABS - Acrylonitrile Butadiene Styrene is a plastic that will be familiar to many modellers, or children - it's what Lego bricks are made from. A much harder material than PLA, it requires higher nozzle temperatures, around 240ºC and a heated print bed is essential. Fumes given off during printing can be unpleasant and many choose an encased printer for this reason.

- PET - PolyEthylene Terephthalate is the most popular plastic in the world. Water bottles are made from it. More flexible than PLA and requiring slightly lower nozzle temperatures than ABS, it's also available in semi-transparent forms. Very sticky while printing, adhesion between layers is excellent, although peeling the model from the print bed can be more of a challenge.

All filaments can be mixed with other materials such as wood or metal if desired, giving the resulting items some of the properties of wood or metal.

So, is 3D printing model railways the future?

Given its potential to span multiple industries, the future of 3D printing looks pretty secure.

Models can be produced in any scale, the only limitation is the size of the printer freeing up the modeller from having to ‘fit in’ with what the trade provides. That could be a boon to those working in 3mm, 5.5mm or S scale. But, conventional scratch-building can do all this too, and sometimes faster than using a printer. A mixture of traditional and printed parts is probably the ultimate solution. If you take time to learn how to draw up your models to print, the combination is very potent.

Overall, we’ve found using a 3D printer simple, and the products well-made and reliable, but don’t expect injection moulding quality unless you have deep pockets to buy a printer. 3D printing model railways, is it the future? It’s definitely going to play an instrumental part.

Looking for some advice on painting 3D model figures? Phil Parker shows how it’s done in this step-by-step video.