17 September 2021

|

Fitting point motors used to mean lots of time-consuming wiring and soldering, but there are now products to simplify this process.

One of the most significant differences between a ‘train set’ and a more advanced more railway is (in most cases) the step up from manually operated points to electrically switched, remotely driven motors.

There are many options available to the modeller working towards this end, from traditional solenoid motors activated by electromagnets to servos and various designs of geared points machines, sometimes known as ‘stall motors’. Whichever type you employ, the electrical connections required to power the motors, change the frog polarity of ‘live frog’ points, link to switches, control panels and mimic diagrams can lead to a veritable ‘rat’s nest’ of wires for every motor - and if you’re using Digital Command Control (DCC), you’ll need to factor in an accessory decoder to send instructions to the motor. To the uninitiated, it can be a daunting prospect and, for many of us, a ‘necessary evil’ before getting to the fun bits of building a layout.

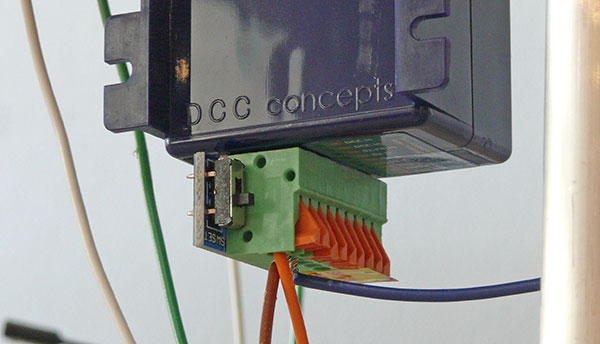

DCCconcepts’ ‘Cobalt’ motors have evolved through several generations, with different versions now offered for analogue and digital control. The Cobalt iP Digital variant (iP is short for ‘Intelligent Power’) has an integrated accessory decoder; installation is no different to other motors of this type and setup is suprisingly simple, especially once you’ve mastered the first one.

1

2

3

4

5

6

7

8

9

10

Struggling to decide on the right DCC decoder for you? Our guide here should be your first port of call.

If you'd like advice on how to set up a DCC decoder, our easy-to-follow tutorial should be your first stop.

For more advice on about DCC, head to our dedicated section.